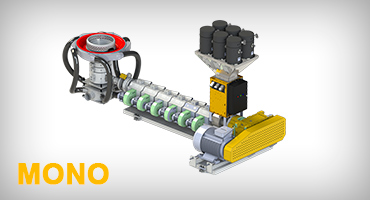

MONO

This type of extrusion lines have single screw feeder and are used to produce ona layer films. 2-4-6 Components Parscontrol gravimetric dosing systems can be used in single-layer extrusion lines such as shrink film, bag film, legumes packaging film, pipe, cast film extrusion lines.

Features for single-layer mono extrusion lines;

● Kg/hour capacity adjustment according to consumption amount.

● Gr/meter output grammage adjustment.

● Theoretical thickness calculation (if film width and components specific weights are entered)

● Continuous capacity (kg/hour) and grammage (gr/meter) monitoring both automatic and manual mode

● Data storage such as production values and recipes

With Parscontrol Dosing;

Settigs and monitoring of capacity (kg/hour), output grammage, thickness and comsumption values for each layer separately. Furthermore, each component of each layer can be arranged with desired ratios and monitored.

Capacity Control

It provides the ability to work with the set production capacity of the machine. The factors regulating the line capacity result in the intervention to the motors operation. It minimizes errors such as contamination and impurity of raw materials.

Grammage Control

It provides precise product weight control at the output. By using the values of consumed amount of raw materials and the actual line speed it continuously controls the product weight at the output and makes it stable.

Smart Component

Quick and Easy Component Discharge With Special Designed Drain Pipes

Available Windows

Transparent Openable Windows for Easy Cleaning and Maintainanc

High Technology

High Quality Industrial Automation Powered by ABB

Industrial Design

Volumes of Reservoirs are Designed for Work With Maximum Capacity Performance

Easy Assembly

Suitable Dimensional Feeder Neck Provide Easy Assembly and if Needed Fast Raw Material Discharge

User Interface

Multilanguage Support, Userfriendly Interface, Full Access for Control and Monitoring

Data Reporting

It Provides the Possibility to Create a Prescription Thanks to the Captured Data

Smart Adjustment

Automatic Adjustment of Output gram/meter Value according to Changes Caused by Filter Choking.